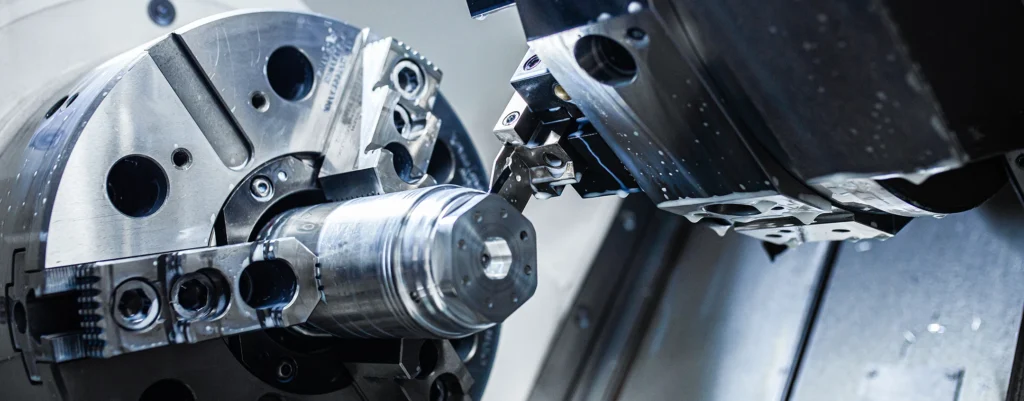

High-Speed Steel Endmills / Drills / Taps: The Ultimate Selection Guide + Real-World Case Studies

In modern machining, selecting the right cutting tool is pivotal. One misstep in choosing an endmill, drill, or tap made of high-speed steel (HSS) can lead to premature tool failure, downtime, and cost overruns. This guide walks you through the process: how to choose among HSS endmills, drills, and taps across geometries, coatings, materials, and machining conditions — and supports all advice with real industrial cases.

HSS Fundamentals & Material Options

What is High-Speed Steel?

High-speed steel is a class of tool steels that maintains hardness at elevated temperatures (red hardness). It offers a balance of wear resistance, toughness, and ease of manufacturing, which keeps it relevant in many cutting tool applications.

Endmills, Drills, Taps: Key Geometrical & Design Considerations

Endmills

Number of flutes: more flutes → more cutting edges, but reduced chip space

Helix angle: influences chip flow, axial force, and vibration stability

Neck relief / reduced shank design: for reach while preserving rigidity

Corner radius, chamfer, and edge honing

Drills

Point angle/chisel edge: typical 118°, 135°, split point designs

Helix angle and flute design: affects chip evacuation

Centring/pilot features or split points

Through-coolant holes / internal cooling if applicable

Taps

Chamfer type: taper, plug, bottoming

Flute style: straight, spiral, spiral-point

Lead/entry design for easier start

Chip evacuation path, especially in blind holes

Selection Emphasis by Workpiece Material & Conditions

Material Categories & Tool Matching

Mild / carbon steels: standard HSS or M2 works well

Alloy steels / stainless steels: consider cobalt (M35 / M42) or PM-HSS

Cast iron / grey iron: benefit from tough edge plus good wear

Aluminum / nonferrous: use polished edges, lower helix, fewer flutes

Cutting Parameters & Coating Strategy

Matching cutting speed, feed, and depth to tool grade

Choosing coatings (TiN, TiAlN, AlTiN, DLC, etc.) to extend life

Trade-off: thicker coatings can reduce sharpness, harder to re-sharpen

Real-World Case Studies

Case 1: M42 TiAlN Endmill vs M2 Uncoated in Stainless Steel

A shop processed 304 stainless with a 4-flute HSS endmill. The M2 uncoated tool lasted ~20 minutes before chipping. After switching to a cobalt M42 substrate with TiAlN coating, tool life jumped to ~65 minutes, with improved surface finish and less burr formation.

Case 2: Deep Hole Drilling with HSS vs Upgraded Cooling

A manufacturer drilled 50 mm deep holes in medium carbon steel using a standard HSS twist drill. Chip packing and heat buildup caused failure within 100 holes. By switching to a through-coolant HSS drill plus internal coolant, life extended to 400 holes — a 4× gain.

Case 3: Pulling Threads in Alloy Steel with Optimized Tap Design

A client had frequent tap breakage when threading 4140 alloy steel. After changing from a standard spiral-point tap to a spiral flute tap with better chip evacuation, adjusting lead chamfer design, and selecting an M35 TiN tap, breakage rate dropped by 90%.

Decision Flowchart & Selection Checklist

Decision Flow Example (pseudo):

Start: Identify material →

Required diameter / depth →

Rigidity/machine capability →

Choose HSS grade →

Select geometry (flutes, helix, lead) →

Decide on coating/treatment →

Verify cooling/holder/run parameters

(可插一个流程图图形 / 图表)

Best Practices & Usage Tips

Minimize stick-out length / maximize rigidity

Use high-pressure coolant / through-coolant where possible

Monitor wear and establish replacement or regrinding thresholds

Edge honing and micro-chamfering help in prolonging tool life

Avoid sudden plunge/shock loads; ramp in gently

Conclusion & Call to Action

Choosing the right HSS endmill, drill, or tap is a multi-dimensional process. Matching substrate grade, coating, geometry, and machining conditions can unlock major performance gains. If you’d like custom recommendations or trials with your parts, feel free to get in touch.