Built for Automotive

Reliable cutting tools engineered for precision machining in steel, aluminum, and alloy components.

Introduction to Cutting Tools for the Automotive Industry

The automotive sector demands speed, accuracy, and repeatability to maintain production efficiency and part quality. From engine blocks to transmission housings, every machined component must meet strict dimensional and surface requirements — often from tough materials such as hardened steel, aluminum alloys, and cast iron.

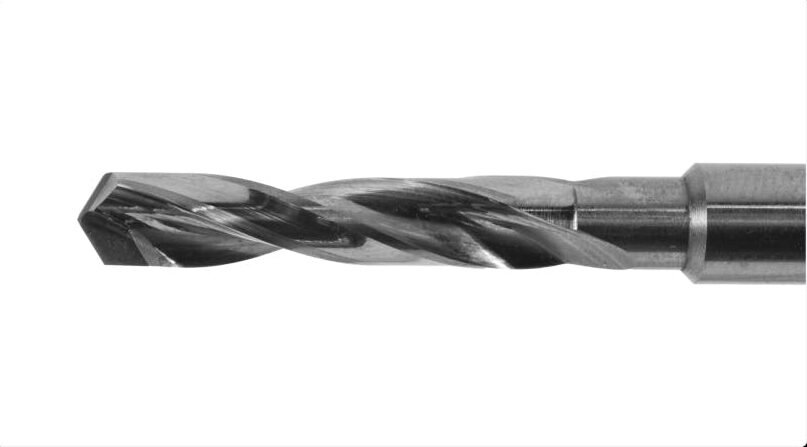

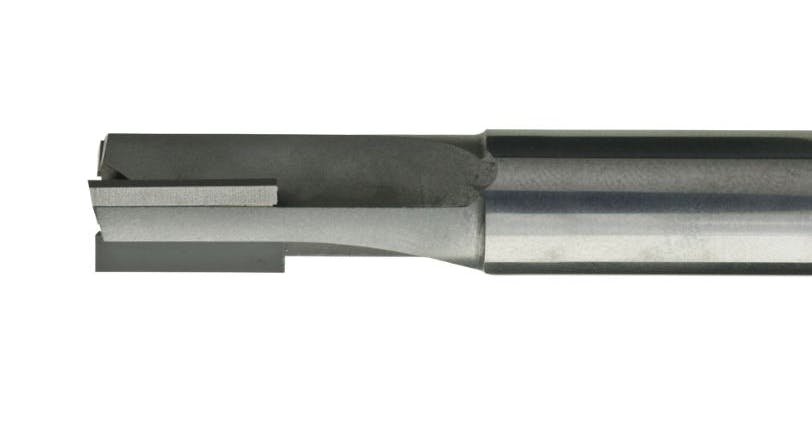

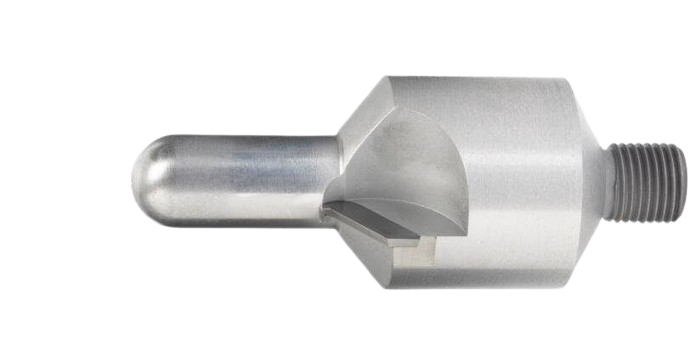

HPCUT delivers high-performance HSS and carbide cutting tools designed for automotive manufacturing lines. Our drills, end mills, and taps ensure consistent chip control, reduced cycle times, and extended tool life — even under high-speed, high-volume machining conditions.

Production Efficiency

Dimensional Accuracy

Automotive Tool Applications

HPCUT tools are trusted by OEMs and Tier-1 suppliers for machining automotive components such as:

- Engine blocks, cylinder heads, and valve seats

- Transmission cases, shafts, and gear housings

- Electric vehicle (EV) motor housings and battery trays

- Brake components, suspension arms, and steering parts

Our cutting solutions are optimised to improve throughput, reduce tool wear, and maintain precise tolerances in both conventional and automated manufacturing environments.

Choose The Right Tool For Your Machining Needs Hpcut Delivers Precision You Can Trust.

Why Choose HPCUT for Automotive Machining

- Consistent results for both ICE and EV manufacturing

- Coated HSS and carbide ranges for extended tool life

- High-speed cutting tools for steel, aluminum, and cast iron

- Optimised geometries for smooth chip evacuation and surface finish

- Custom tool design available for specific component geometries

🧰 Automotive Cutting Tool FAQs HPCUT

We ensure fast turnaround times, with most standard tools ready to ship within 7–10 working days.

HPCUT recommends using carbide and HSS end mills or drills with advanced coatings for machining cast iron, steel, and aluminum components.

Yes, HPCUT’s engineering team can develop tailored tool geometries and coatings for your exact application and material.

Yes our tools are engineered for stable performance and long life, even under continuous, high-speed CNC machining conditions.

Absolutely. We offer specialised cutters for EV housings, battery casings, and lightweight aluminum structures.