Built for General Machining

Reliable cutting tools engineered for everyday precision across steel, aluminum, and alloy materials.

Introduction to Cutting Tools for General Machining

General machining covers a wide range of metalworking and workshop applications, from small-batch production to custom part fabrication. In these environments, cutting tools must deliver accuracy, repeatability, and efficiency across various materials — including mild steel, stainless steel, aluminum, and cast iron.

HPCUT provides a complete range of HSS and carbide cutting tools designed for daily machining operations. Whether you’re drilling, milling, or tapping, our precision tools deliver stable performance, extended tool life, and consistent surface finish — ensuring reliability in every operation.

Machining Efficiency

Dimensional Accuracy

General Machining Tool Applications

HPCUT tools are trusted by machine shops, tool rooms, and production facilities for a variety of machining tasks, including:

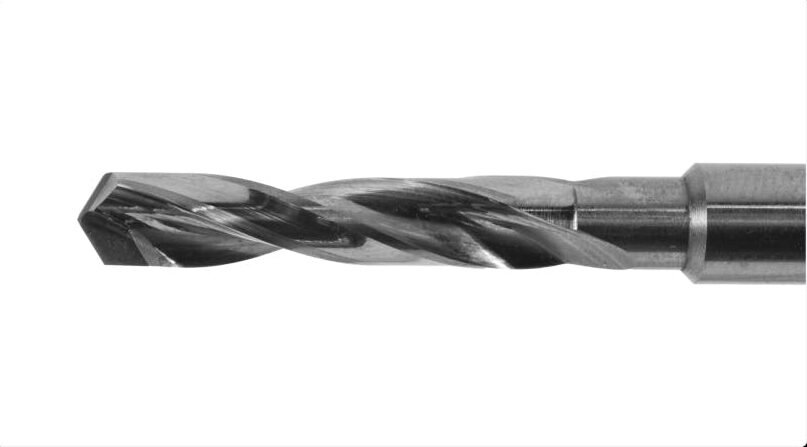

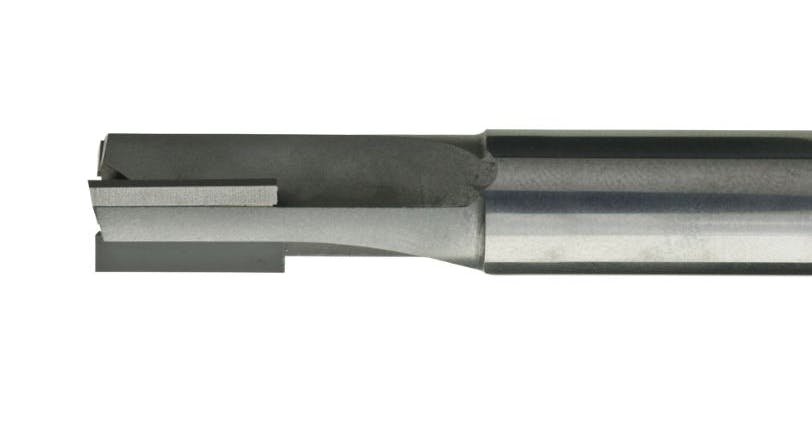

- Precision drilling and reaming for mechanical parts

- Tapping and thread cutting for assemblies and fixtures

- Milling and slotting of steel and aluminum components

- Maintenance and repair machining in workshop environments

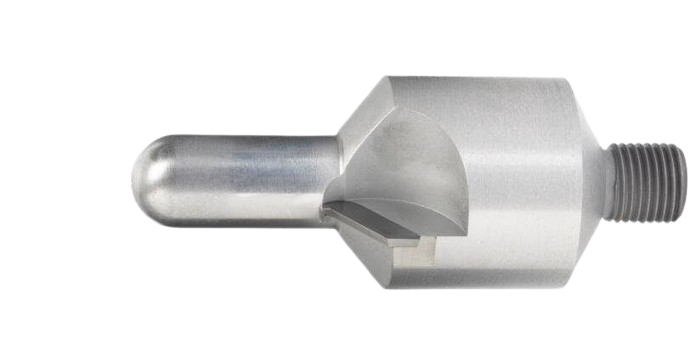

- Finishing and deburring of small-batch or prototype components

Our tools are designed for smooth cutting action, reduced vibration, and longer tool life, ensuring dependable performance across general manufacturing needs.

Choose The Right Tool For Your Machining Needs Hpcut Delivers Precision You Can Trust.

Why Choose HPCUT for General Machining

- Fast delivery and ISO-certified quality control

- Optimised flutes for smooth chip flow and clean finish

- Suitable for manual and CNC machining setups

- Heat-resistant coatings for extended tool durability

- High-performance HSS and carbide tools for everyday applications

🛠️ General Machining Cutting Tool FAQs – HPCUT

HPCUT’s HSS and carbide end mills, drills, and taps are ideal for machining steel, aluminum, and cast iron components in everyday workshop operations.

Yes — all our tools are designed for versatile use, providing stability and precision in both CNC and conventional machining setups.

Absolutely. Our coatings and geometries are engineered for multi-material compatibility, allowing efficient machining across various metals.

With optimized geometry and superior wear resistance, HPCUT tools reduce downtime, improve finish, and extend tool life — boosting overall productivity.

We maintain rapid delivery timelines, with most standard tools ready to ship within 12 working days.