Built for Mold Manufacturing

High-precision cutting tools designed for die and mold machining with superior accuracy and durability.

Introduction to Cutting Tools for the Mold Manufacturing Industry

Mold and die manufacturing demands exceptional surface finish, dimensional precision, and tool strength. Whether machining hardened steel, graphite electrodes, or aluminum molds, every detail must be accurate to the micron.

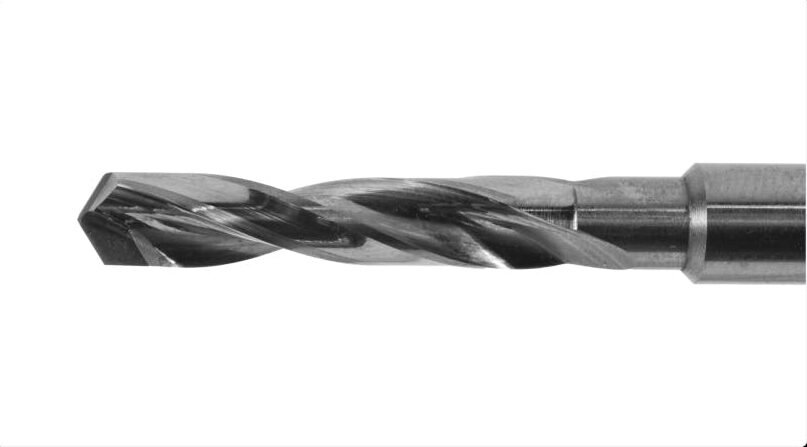

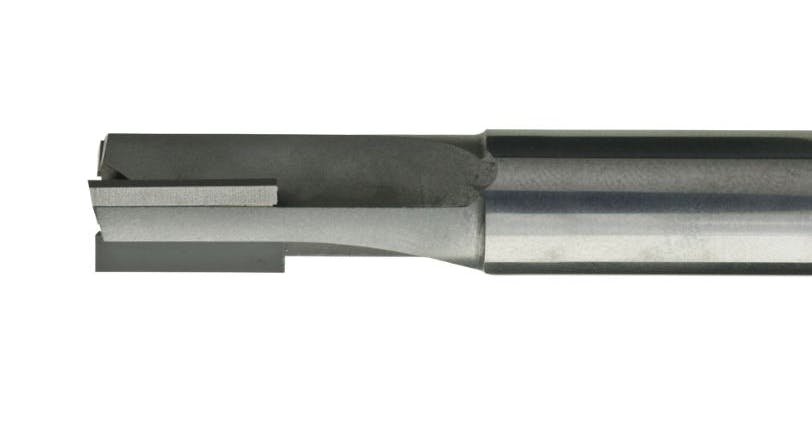

HPCUT offers a complete range of carbide and HSS cutting tools engineered for high-speed, high-accuracy mold machining. Our end mills, drills, and ball nose cutters deliver mirror-like finishes, reduced machining time, and extended tool life, helping manufacturers achieve faster mold production with consistent results.

Surface Finish Quality

Machining Efficiency

Mold Manufacturing Tool Applications

HPCUT cutting tools are trusted by toolmakers and mold manufacturers for a wide range of applications, including:

- Injection molds and die-casting tools

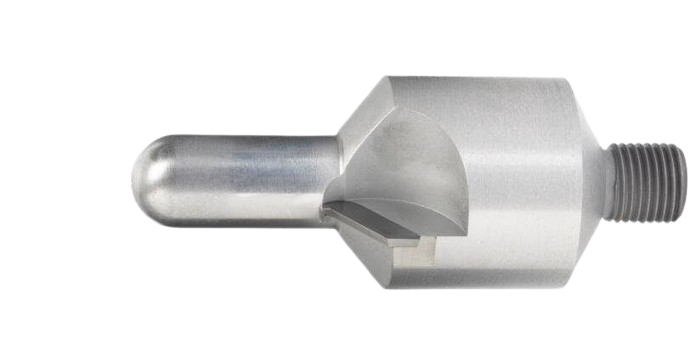

- 3D contour milling and cavity finishing

- Graphite and copper electrode machining

- Precision finishing for plastic and metal molds

- Core and cavity roughing with high material removal rates

Our tools ensure exceptional dimensional accuracy, reducing the need for polishing and secondary finishing operations.

Choose The Right Tool For Your Machining Needs Hpcut Delivers Precision You Can Trust.

Why Choose HPCUT for Mold Machining

- Flute geometry for cleaner cuts and smooth finish

- Fast delivery and ISO-certified quality assurance

- Custom tool design for complex mold shapes and deep cavities

- Ultra-fine carbide and HSS tools for hardened steel and graphite machining

- Advanced coatings (TiAlN, DLC, Diamond) for heat and wear resistance

⚙️ Mold Manufacturing Cutting Tool FAQs HPCUT

Yes our high-precision finishing tools deliver near-mirror surface finishes, minimising polishing time and improving mold quality.

Yes our tools are optimised for high-speed machining, helping you cut material faster while maintaining precision and tool stability.

Our carbide ball nose end mills, roughing end mills, and drills are ideal for machining hardened steel, copper, and graphite materials used in mold production.

Absolutely. HPCUT provides custom-engineered tools tailored for deep cavities, fine details, and specific mold geometries.

Our advanced coatings such as TiAlN, Diamond, and DLC improve heat resistance, reduce friction, and extend tool life significantly.