Built for Aerospace

Introduction to Cutting Tools for the Aerospace Industry

The aerospace sector demands absolute precision, consistency, and reliability. Every component from fuselage structures to landing gear must meet exacting tolerances and surface finish requirements while being machined from challenging materials such as titanium, Inconel, and advanced composites.

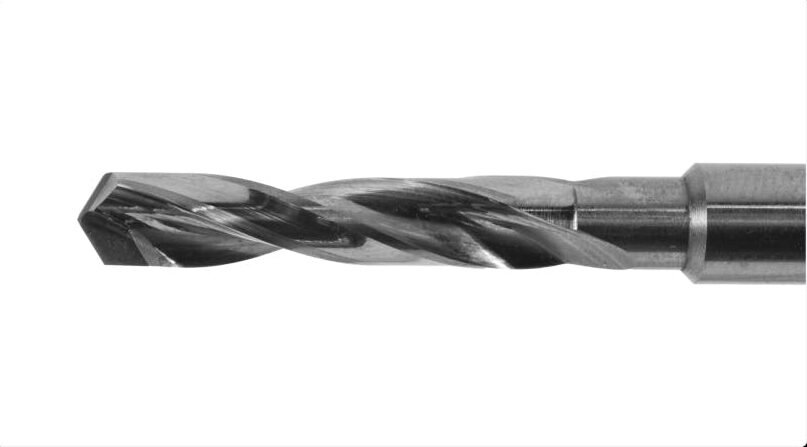

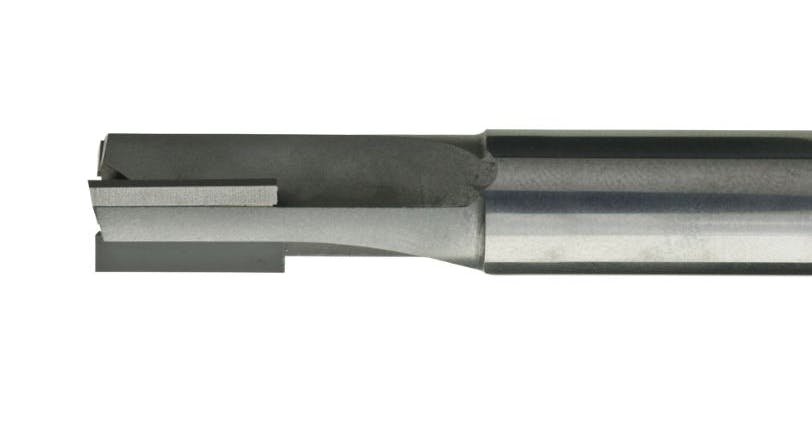

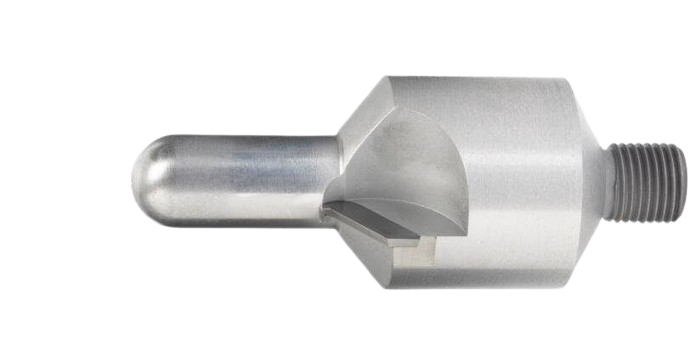

HPCUT provides high-performance cutting tools designed specifically for aerospace manufacturing. Our HSS and carbide-based drills, end mills, and taps deliver exceptional tool life, stability, and dimensional accuracy ensuring clean, burr-free results even under high speed cutting conditions.

Aerospace Tool Applications

- Composite material drilling for wings, panels, and fuselages

- Producing engine mounts, landing gear, and control housings

- Machining titanium and aluminum alloys for structural components

- Supporting MRO (Maintenance, Repair & Overhaul) operations for aircraft components

Choose The Right Tool For Your Machining Needs Hpcut Delivers Precision You Can Trust.

Why Choose HPCUT for Aerospace Machining

- Faster cutting speeds with stable performance

- Extended tool life through advanced coatings and geometries

- High precision & consistency in difficult-to-machine materials

- Custom tool solutions available for specific aerospace components

✈️ Aerospace Cutting Tool FAQs HPCUT

Yes. Our PCD and carbide tools can be professionally re-tipped or re-sharpened to restore performance and reduce long-term tooling costs maintaining accuracy and reliability with every use.

Delamination can be avoided by using optimized point geometry and diamond-coated drills designed by HPCUT for composite layers. Our tools ensure smooth entry and exit, even in CFRP–Titanium or CFRP–Aluminium stacks.

Absolutely. We provide custom and standard tooling solutions for both military aircraft production and MRO (Maintenance, Repair & Overhaul) applications — from structural repairs to component refits.

Yes. Our technical support team works directly with your engineers to recommend the ideal tool geometry, coating, and grade based on your material type, tolerance needs, and machining setup.

With in-house production and advanced CNC manufacturing, we ensure rapid lead times, with most aerospace tools shipped within 7–10 working days, including custom configurations.